Introducing

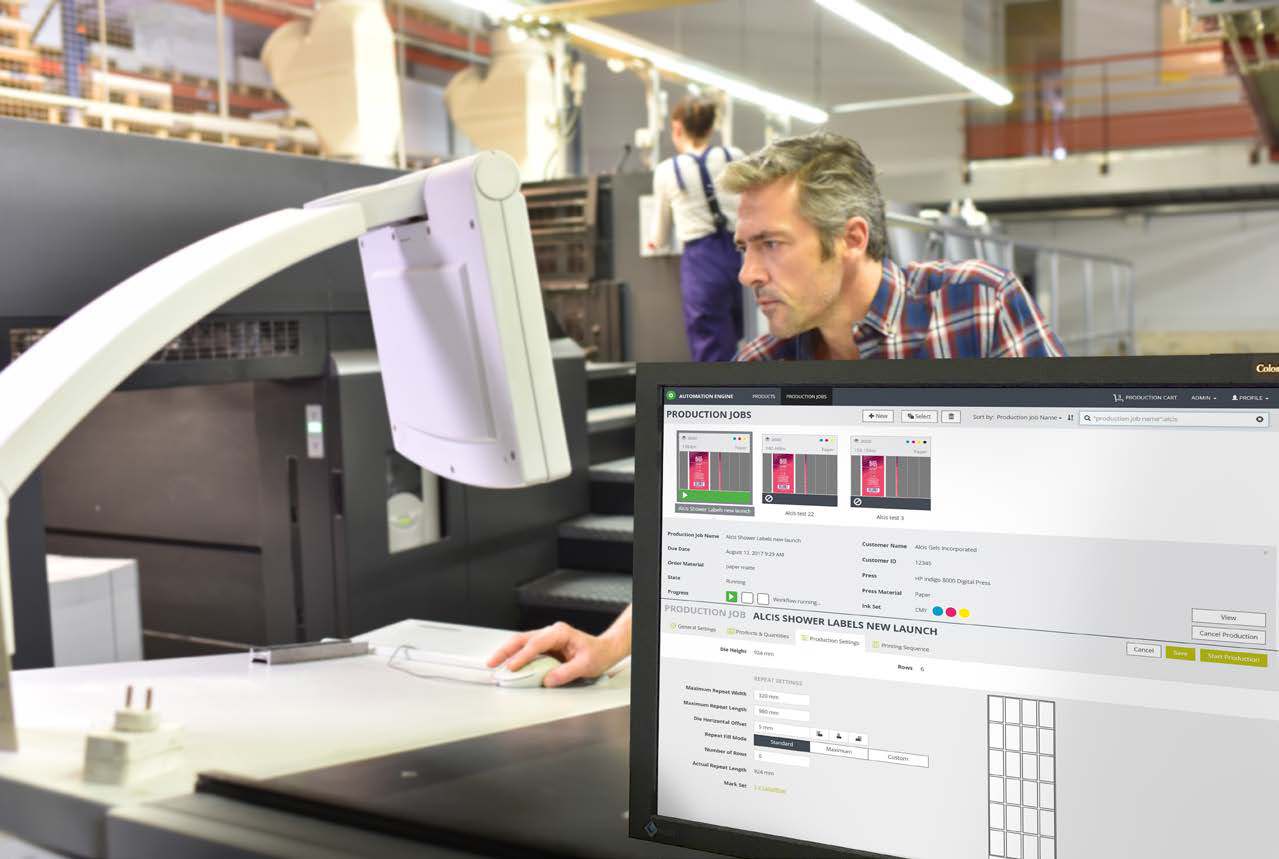

Automation Engine QuickStart for Labels

The new Automation Engine QuickStart for Labels is a turnkey solution for label converters.

Based on Esko’s Automation Engine, the QuickStart package comes preloaded with proven workflows for label production.

And with just 5 days to get you up and running, you start reaping the benefits of automation almost immediately.

QuickStart is the ideal entry level workflow for label printers with digital and/or conventional printing).

Label One-Up Process Flow

Product Creation

Automation Engine QuickStart for Labels organizes data and connects your people. In a world with an increasing number of shorter print runs, getting data organized is a huge win: operators get more done, in less time.

Quality Control

Automation Engine QuickStart for Labels comes with integrated quality control tools: Packaging preflight. Incoming files are checked against Enfocus PitStop profiles. Packaging specific checks include checking the presence of a barcode, the barcode type, the barcode value, restrictive checking to the inside of the die cut…

A fully featured viewer helps you to perform quality checks on the file. Zoom into any depth, accurately measure distances, separations, colors so that you can make sure the design is fit for print, avoiding costly errors later on in the process.

Approval

Automation Engine QuickStart for Labels makes approvals a breeze. The right people get the right files to give the go ahead. The status of every product (waiting for prepress, waiting for approval, approved) is clearly visible to all users, avoiding wasted time in communication.

Trapping

Files are trapped automatically with Esko’s market leading technology. Even complex files are trapped expertly without operator intervention.

Reporting

Reports (also known as “Job cards” or “good for print” sheets) are a requirement for communication and sign-off with stakeholders within and outside the label printer.

Automation Engine QuickStart for Labels creates reports by adding information such as job name, customer, inks required…to an image of the job. These reports are in standard PDF which can easily be viewed on any desktop or tablet platform.

Creating these reports manually would take several minutes per job: automation of this routine task allows your operators to focus on value added activities

Step & Repeat

The last step is automated layout creation. Your files are step & repeated, and marks for your press and finishing line are added. The resulting print ready file is ready to send to a DFE for digital printing, or to a RIP for conventional flexo or offset platemaking.

A system that grows with you

Automation Engine QuickStart gets you automated in less than a week, but it is not a limited solution.

As your business grows, Automation Engine grows with you. If you need additional throughput, integration with upstream systems or connections with new production equipment, Esko has a broad range of upgrade modules.

And, because QuickStart is part of Esko’s Automation Engine platform, these modules click into place easily and simply.

MIS integration

Automation Engine for Labels is ready to integrate with market-leading MIS systems to create a fully connected end to end workflow. MIS integration means that there is no longer any need to re-enter data known to the MIS, such as order quantities. This saves valuable time and avoids the possibility of errors.

Intelligent color preflight

Color Preflight (add-on option) finds the fastest and most cost effective way to print jobs on an HP Indigo digital press, while meeting brand color expectations. This optimizes cost and makes additional production time available on the press.