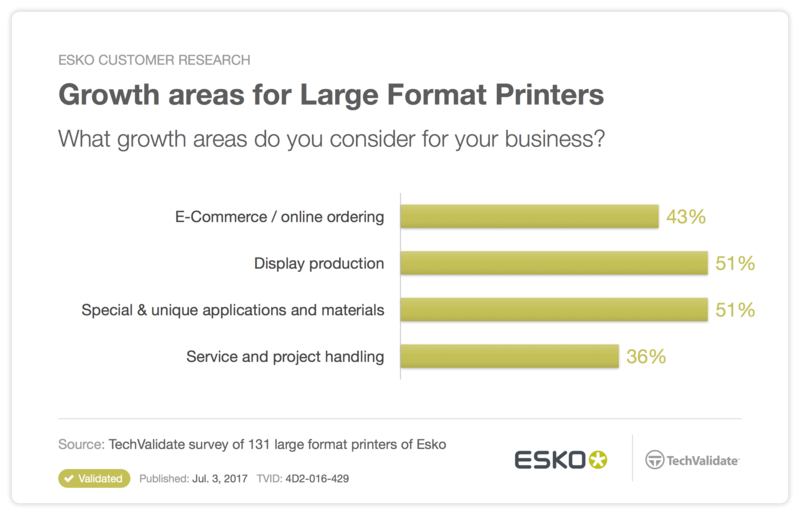

Looking for ways to expand your digital printing business?

Download our free whitepaper and learn about:

- Trends & market opportunities

- Delivering predictable & accurate performance

- Eliminating waste

- Cases studies from print shops that have improved productivity

Find new opportunities

As wide format printing technology has advanced with new inks and media types there’s a distinct need for workflows that are a bit more sophisticated.

Every company has a way of doing things, all workflows are different but identifying waste in your workflow helps finding opportunities.

This white paper from ISA and Esko, and compiled by InfoTrends, explores the ways digital printing is transforming the packaging, signage and display supply chain. It also offers insight in ways to reduce waste in your workflow.

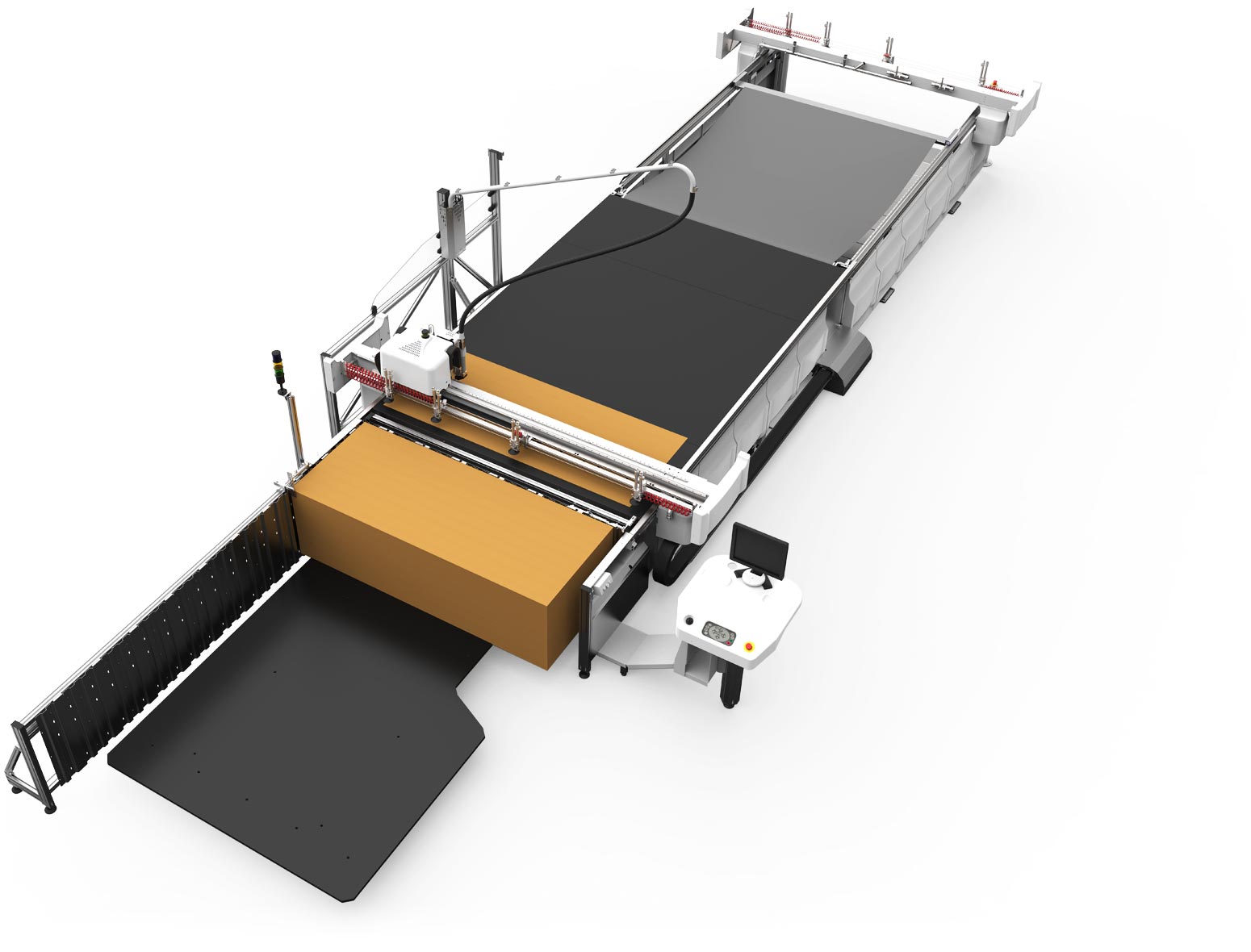

We had invested in a fast flatbed digital printer that was capable of working with 5 x 10-foot materials.

It was a monster at pushing out products, so we really had no choice but to invest in a finishing table that could handle that output. The Kongsberg XP offered speed, price, and quality, and we also liked the size. – Tina McLaughlin, President and Owner of Great Big Color, United States

It was a monster at pushing out products, so we really had no choice but to invest in a finishing table that could handle that output. The Kongsberg XP offered speed, price, and quality, and we also liked the size. – Tina McLaughlin, President and Owner of Great Big Color, United States

Reduce waste in your workflow

Waste is found in each production step:

- Rejects or overproduction

- Idle production equipment (OEE)

- Lack of shop floor communication

- Files waiting in a mailbox creating a bottleneck

The key to workflow efficiency is to identify any areas of waste and standardize the process. Esko helps companies to get rid of bottlenecks or waste, streamlining the process and protecting the bottom line.